Livox News

Livox und Xpeng läuten neues Kapitel in der Massenproduktion von integrierten Lidar-Geräten ein

2021-1-1Livox will be supplying automotive-grade lidar technology for XPeng’s new models slated for mass production starting 2021. This will provide the smart electric car maker with an industry-leading perception solution, in its bid to deliver a smart driving experience with superior safety and comfort.

January 1, 2021. Livox, the world’s leading lidar maker, has formed an official partnership with leading smart electric vehicle company Xpeng, becoming the first partner in the lidar technology field for Xpeng. Livox will be supplying automotive-grade lidar technology for Xpeng’s new models slated for mass production starting 2021. This will provide the smart electric car maker with an industry-leading perception solution, in its bid to deliver a smart driving experience with superior safety and comfort.

Joining Forces to Push the Frontiers of Smart Driving

Since its founding in 2016, Livox team has consistently focused its research and development efforts on enabling the mass production of lidar solutions in a cost-efficient manner, with the goal of overcoming the three bottlenecks in the lidar industry: high price, low production scalability and poor reliability. After four years of R&D, and backed by its expertise in smart hardware manufacturing and global supply chain management, Livox launched a series of brand-new automotive lidar products in 2020, marking a new milestone for the mass production of lidar industry.

Livox and Xpeng’s collaboration is a timely response to a new era of rapid advancements in self-driving technology and the rising popularity of software defined cars with upgradable hardware. The application of lidar will elevate the smart driving experience by minimizing the limitations posed by purely visual perception solutions, and providing added levels of safety for smart electric vehicles.

As one of the world’s leading smart EV companies, Xpeng is committed to revolutionizing data-driven smart electric cars, and answering the needs of a huge and growing number of tech-savvy consumers. Xpeng is a visionary innovator that is constantly breaking new grounds and embracing cutting-edge technology, bringing autonomous driving technology to production vehicles.

Customized Automotive-grade Livox Lidar Takes Xpeng’s XPILOT to the Next Level

For this collaboration, Livox has completed a series of customizations for Xpeng using its Horiz sensor (automotive-grade version of Livox Horizon), with its final mass-produced version boasting a range of industry-leading features. For instance, the detection range of Horiz will be increased to 150m from the 90m of the public sample version Horizon (for objects at 10% reflectivity). This will enable Xpeng’s XPILOT autonomous driving system to detect any remote obstacle much earlier with absolute ease while on highways and urban roads. Meanwhile, the resolution of Horiz also doubles its public sample version, with the new ROI (Region Of Interest) point cloud density increased to 144 lines equivalently at 0.1 second without the need for adding extra laser transmitters. The increased point cloud density enables the faster detection of tiny objects on the road surface, including pedestrians, bicycles or even traffic cones. The horizontal FOV (Field Of View) of Horiz has also been expanded to 120° from the 81° of Horizon. This greatly enhances the smart driving experience by resolving many persistent challenges faced by drivers, including the removal of blind spots against cut-in vehicles.

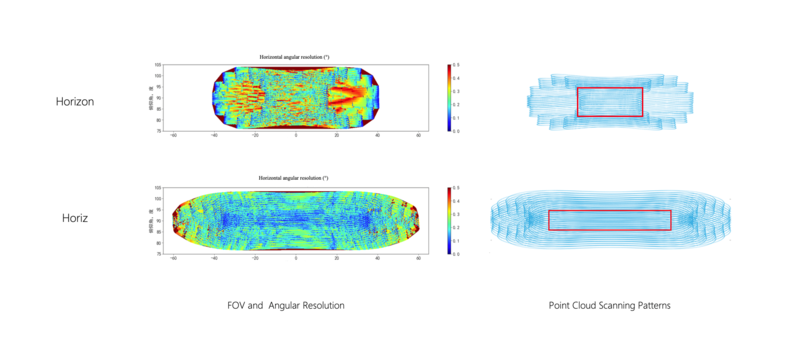

Comparison between Horiz (Left) and Horizon (Right)

In its product development process, Livox has embraced the ethos of striving for top performance through simple product designs, and developed a brand-new “ultra FPS” (Frames Per Second) lidar technology concept: Through a cleverly designed rotating-mirror technology, the objects within the lidar’s ROI of FOV will be scanned twice against the rest area, namely the ROI will acquire a 20Hz point cloud data when the whole system is working at a frame rate of even 10Hz. This solution will greatly lower the potential risk of car accidents when the vehicles are running at high speeds or surrounded by crowds of pedestrians and bicycles, which is a typical public road phenomenon in China. Moreover, the scanning patterns of Horiz are flatter and more even than the normal version. These patterns are more compatible with the existing main-stream point cloud algorithms, and makes the development of algorithms much easier.

Comparison of FOV and scanning pattern between Horizon and Horiz

Entering the New Era of Mass Production at Greater Cost Efficiency

The lidar supplied to Xpeng will be produced at Livox’s own brand-new automotive-grade manufacturing center. Equipped with world-leading SMT (Surface Mount Technologies) production lines with the designed PPM (Parts Per Million) at 10 and fully automated and streamlined production processes, the manufacturing center will be able to meet Livox’s future expanding needs for the efficient production of its own core lidar components. Meanwhile, the lidar assembly lines will deliver an annual capacity of 100,000 pieces per year per line, and any expansion of assembly lines and production capacity in the event of increased customer demand can also be achieved within three months. Besides, Livox will be establishing its own independent test center based on CNAS (China National Accreditation Service for Conformity Assessment) standards. The center will enable over 70 items of the automotive-grade reliability tests, and ensure reliability requirements are met in the product development process through its top-class facilities.

Apart from its impressive manufacturing and testing capabilities, Livox has played an important role in helping to lower the material cost for lidar. Through its simplified product design and the cost benefits reaped from scale purchasing, Livox is the first company in the global lidar industry to provide cost-effective automotive-grade lidars. The company’s industry-leading manufacturing capability has also boosted its production efficiency and lowered the failure rate, which in turn reduced the cost. Livox has amassed a wealth of experience in adapting precision manufacturing requirements to mass production needs, through the continuous supply of its product solutions to various sectors in the past two years, such as robotics, mapping, security, railway, and robo-truck. This has paved the way for the industry’s ability to meet the demand of the rapidly growing market for mass produced automotive-grade lidars. Through its collaboration with Xpeng, Livox’s position in the industry as the revolutionary pioneer is further enhanced, with its commitment to making lidar more affordable and empowering lidar’s application in a wider range of AI scenarios.

Leading the Way as the “Eye” Of Autonomous Vehicles

As we approach the era of smart vehicles, consumers are exhibiting an increasing demand for a more comfortable and safer autonomous driving experience that is no longer a concept far out of reach. The partnership between Livox and Xpeng is motivated by the shared goals of providing users with a safer driving experience, by dramatically reducing the rate of accidents caused by relying solely on visual perception, and making cutting-edge technologies available in production vehicles. By working with Xpeng, Livox is committed to developing safer lidar technologies for the autonomous driving systems of the future, and becoming the “eye” of self-driving vehicles in propelling the industry forward.